Far Infrared Finishing Agent TexTrit FR

1

Zhejiang Holposon New Material Co., Ltd, HOLPOSON for short, was founded in 2017 by a young doctor returning from Canada.

HOLPOSON is a comprehensive technical professional organization integrating functional additive technology research and development, techical services, technical applications, and technical sales.

Three series of new textile finishing agents, PreTrit, ColTrit, and TexTrit, have been developed in the pretreatment, dyeing and after-finishing processes, which have been widely used in textile printing and dyeing processing enterprises.

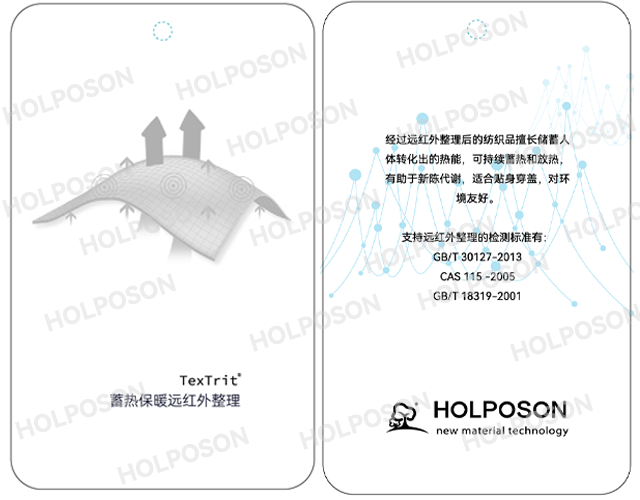

Long term storage

Far Infrared Finishing

Good washing resistance

Physical & chemical properties:

Composition: Special ceramic powder, etc.

Appearance: White weak viscous liquid

Ionicity: Nonionic

pH: 6-7

Characteristics:

is mainly composed of special ceramic powder, which can be stored for a long time. This product is a multifunctional finishing agent developed by doctors from Donghua University. Besides the function of far infrared rays that rise the sensible temperature on human body, it also has the function of deodorizing and absorbing peculiar smell. It is a multifunctional finishing agent with added value. Suitable for finishing cotton, viscose, wool, acrylic/wool, polyester, nylon and other fibers. FR treated fabric has good hand feel and wash durability.

Testing standard

The following testing standards are supported:

GB/T 30127 CAS 115

Usage:

Dosage: Depends on different types of materials to be treated, generally 3.0-5.0% (o.w.f.)

1. Padding method

Dosage: FR 30-60g/L

Treatment method: dip and roll once, with liquid rate of about 80%, drying and heat setting at 160-180 ℃

2. Impregnation method (applicable to cotton and viscose)

Dosage: 3.0-5.0% (o.w.f.)

Dissolve evenly to prepare the working solution → Impregnation temperature 40-60 ℃ (20-30 minutes) → dehydration (about 50% of liquid content) → drying (100-120 ℃)

Storage:

Storage time: 12 months

Keep indoor and avoid overheat or severe cold

The optional packages are: 1kg/2kg/5kg/10kg/25kg/60kg/100kg/120kg

To install this Web App in your iPhone/iPad press ![]() and then Add to Home Screen.

and then Add to Home Screen.